The Finite Element Method has become a necessary tool for the design of complex structures.

Nowadays, the industry needs high efficiency – lightweight structures and smart solutions in terms of production feasibility and cost.

Within Safe-Structures, sophisticated Finite Element software are used for the calculation of structures using beam and/or plate elements. We are experienced in the use of all relevant industrial standards and norms, provided by the classification societies, Eurocode, ASME etc. With the Finite Element Method, we are able to design complicated ship structures, steel supports for various production plants, steel buildings and wind turbines.

Also, Modal and Vibration analysis are part of our services. Using the modal and vibration analysis we are able to validate if the frequency excited by the installed equipment, resonates with the eigenfrequencies of the surrounding structure. This is a very useful method that can be applied on many types of structures, such as azimuth thruster foundations mounted on ship structures, wind turbines, diesel engines, generators and in general all types of rotating equipment.

In addition, within Safe-Structures we have developed automated scripts which are boosting our workflow effectively. We are able to apply loads or export variable results for multiple load cases.

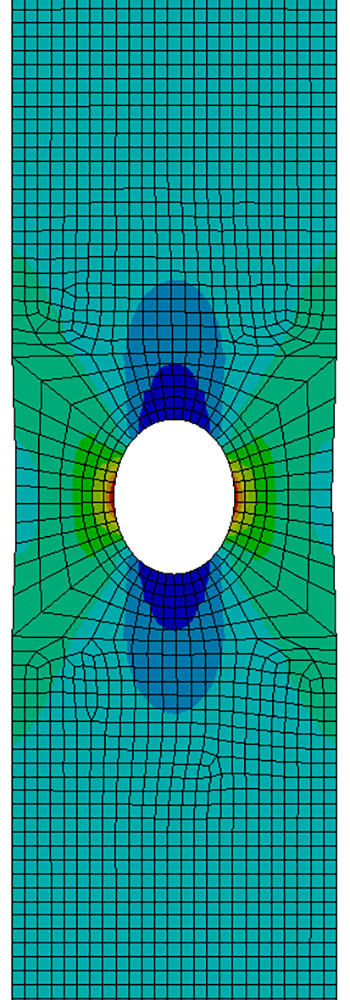

Also, one of the key features we use is, “Sub-Modeling”. With sub-modeling we are able to investigate in depth local models which are part of larger global models. We fist export the rotations and translations from the global model and we apply them to local models with finer mesh. This tool helps us obtain accurate results in shorter calculation times.

During our analyzes we perform yield and buckling checks in accordance to the relevant industrial standards.

Safe-Structures structural designs are focusing on the optimal weight, production feasibility and low cost.